Production Process in Setting up and managing a garment factory is a highly technical and data-driven task. Success in the garment manufacturing industry depends not only on product quality and style but significantly on the efficiency of the production process. At Lord Industrials Pvt. Ltd., we specialize in end-to-end garment factory setup and optimization — from layout planning to productivity enhancement, with practical, cost-effective engineering solutions.

This blog about Production Process in a Garment Factory provides a comprehensive guide on the production process in a garment factory. It covers every critical stage including cutting, sewing, bundling, and layout design, supported by industrial best practices, problem identification, and practical improvements.

🧩 1. Understanding the Core Framework of Garment Production Process

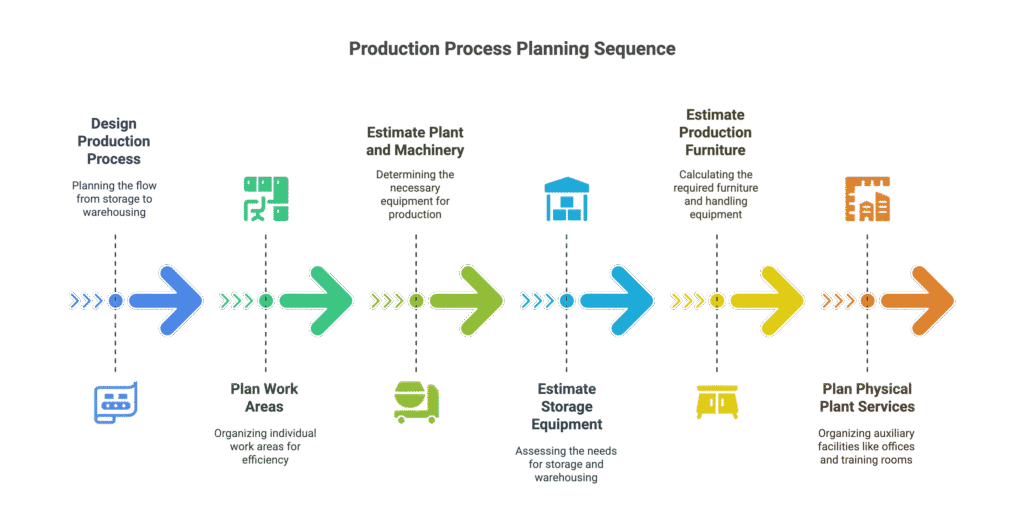

A well-functioning garment factory relies on four major pillars:

🔹 Input

The essential resources used in the manufacturing process:

- Manpower: Operators, helpers, supervisors, quality inspectors.

- Materials: Fabric, trims, threads, accessories, packaging.

- Machines: Stitching machines, cutting machines, pressing equipment, and handling tools.

- Methods: Standard Operating Procedures (SOPs), process flow, motion sequences, and documentation systems.

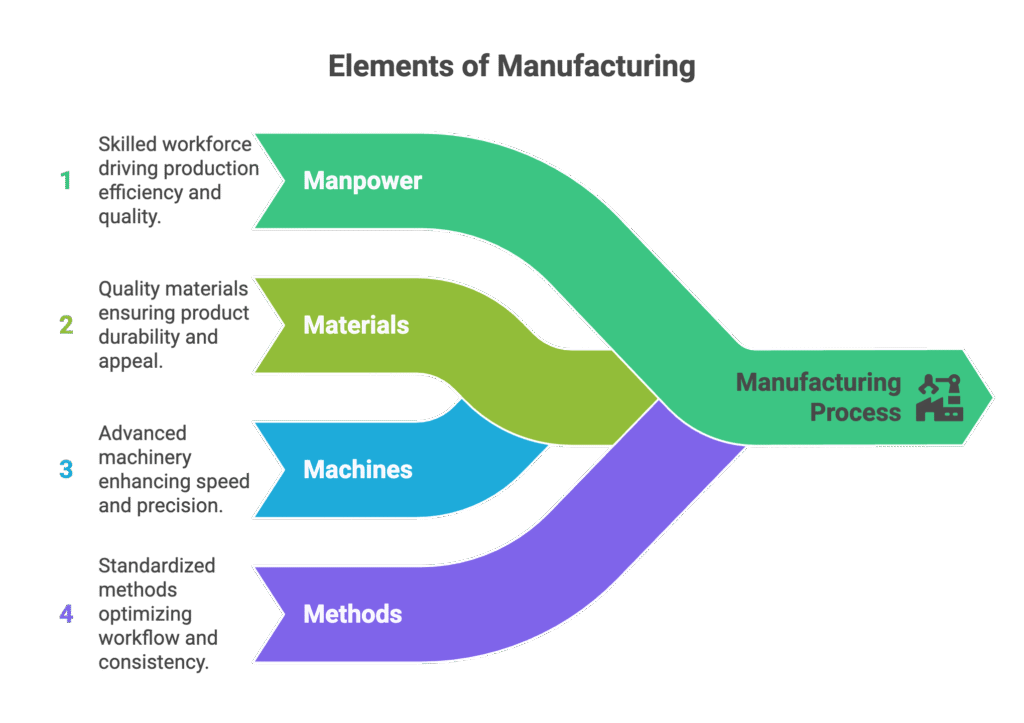

🔹 Method Management

Focuses on organizing workflow, time management, layout planning, and operational discipline.

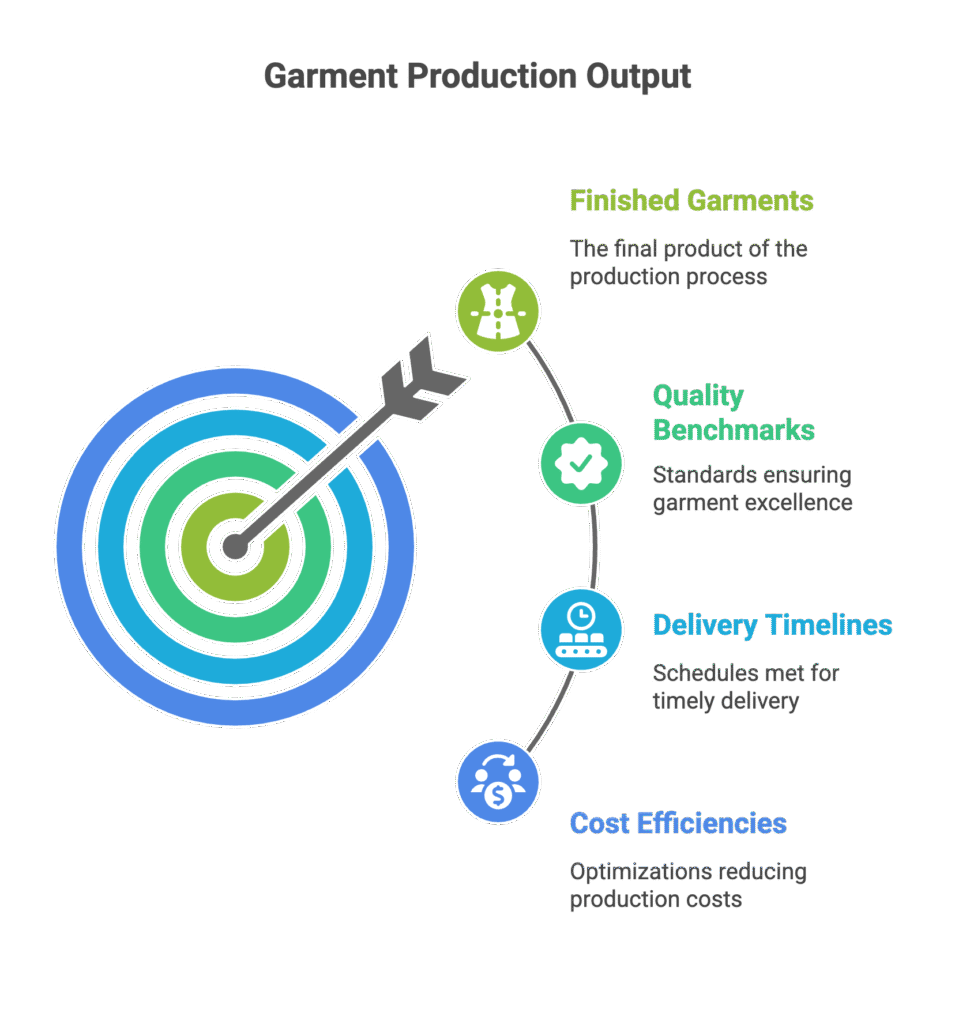

🔹 Output

Refers to the finished garments, quality benchmarks achieved, delivery timelines met, and cost efficiencies realized.

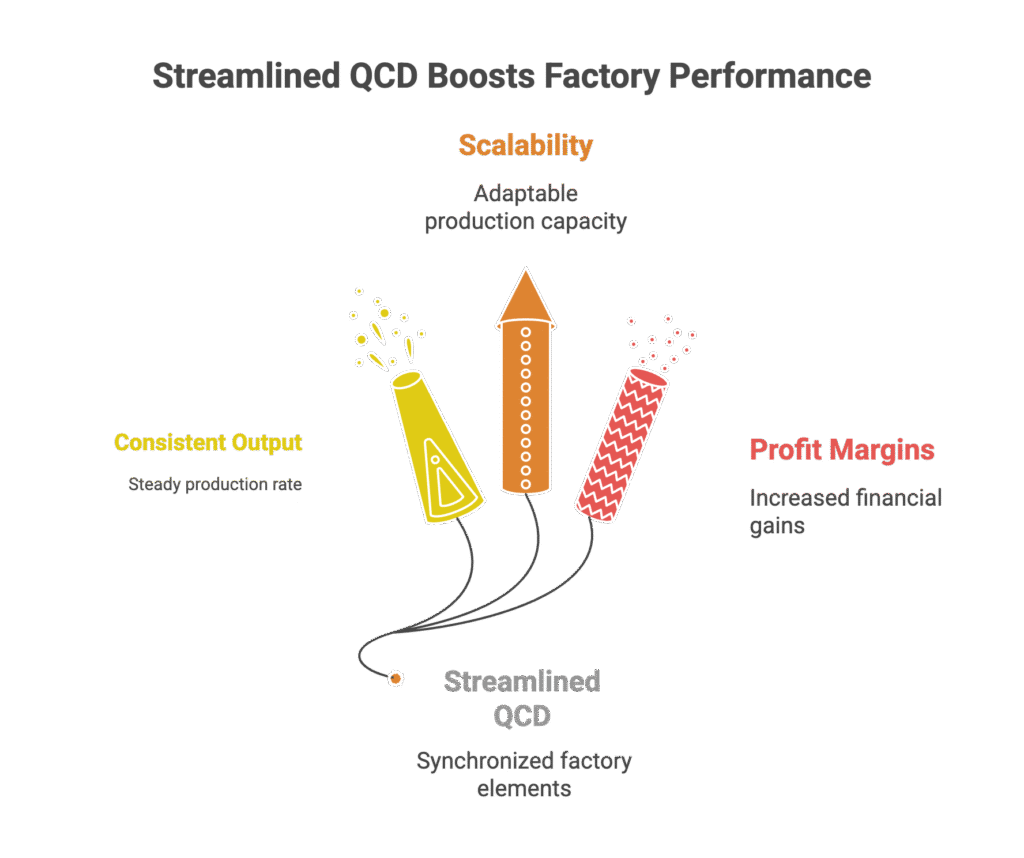

🔹 Evaluation Standards: QCD

Garment factories are evaluated based on:

- Q – Quality of finished products.

- C – Cost per unit.

- D – Delivery timelines and speed.

When all these elements are streamlined and synchronized, the factory becomes a high-performing ecosystem that drives consistent output, scalability, and profit margins.

✂️ 2. Cutting Section – Foundation of Production Accuracy

The cutting section plays a pivotal role in defining both the quality and cost structure of a garment. Any error here multiplies across the sewing line.

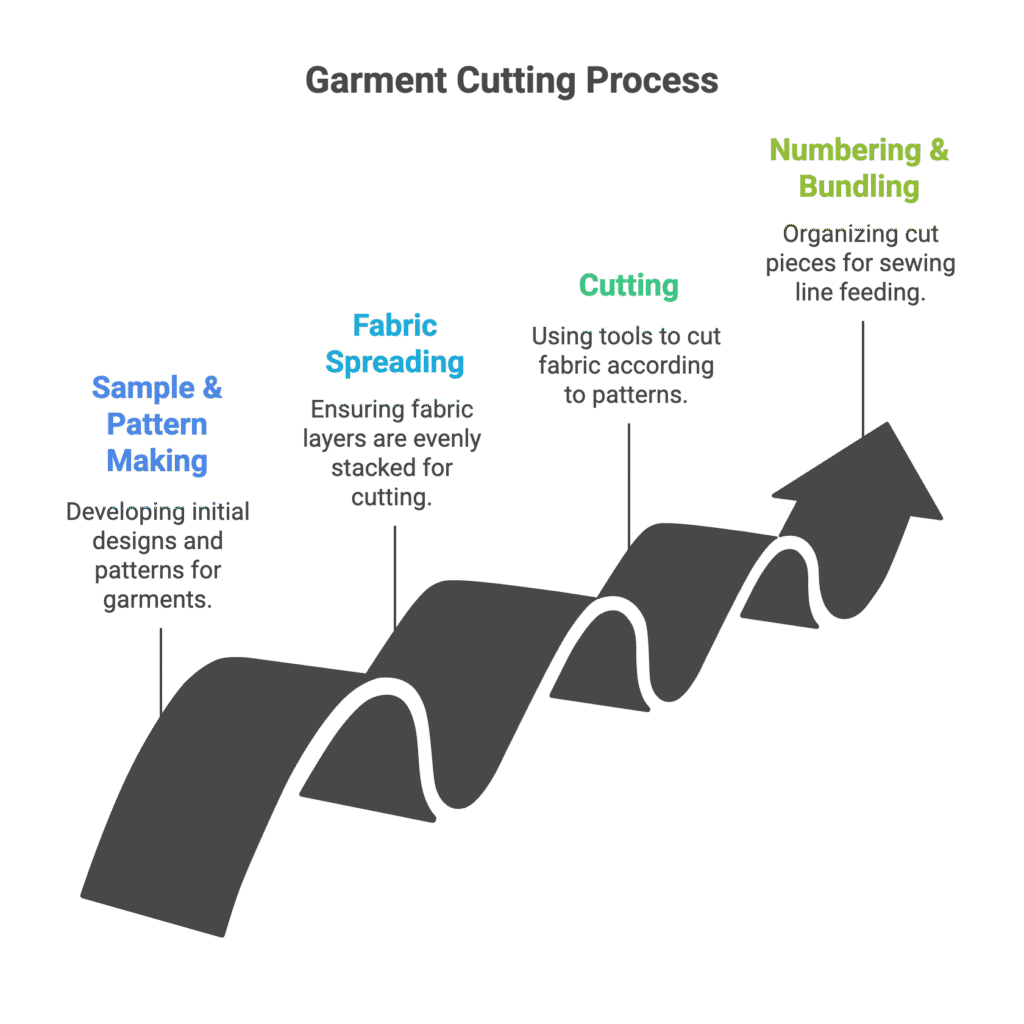

Key Steps in the Cutting Section:

📐 a) Sample & Pattern Making

Garments begin with sample development and pattern drafting. The master pattern is graded for various sizes.

🧾 b) Fabric Spreading

Manual or machine-based spreading ensures multiple layers of fabric are stacked evenly for cutting.

🔪 c) Cutting

Tools like straight knife, band knife, or laser cutting machines are used for bulk cutting as per the marker plan.

🔢 d) Numbering & Bundling

Each cut component is numbered to track size and layer identity. Bundling is done section-wise for smooth sewing line feeding.

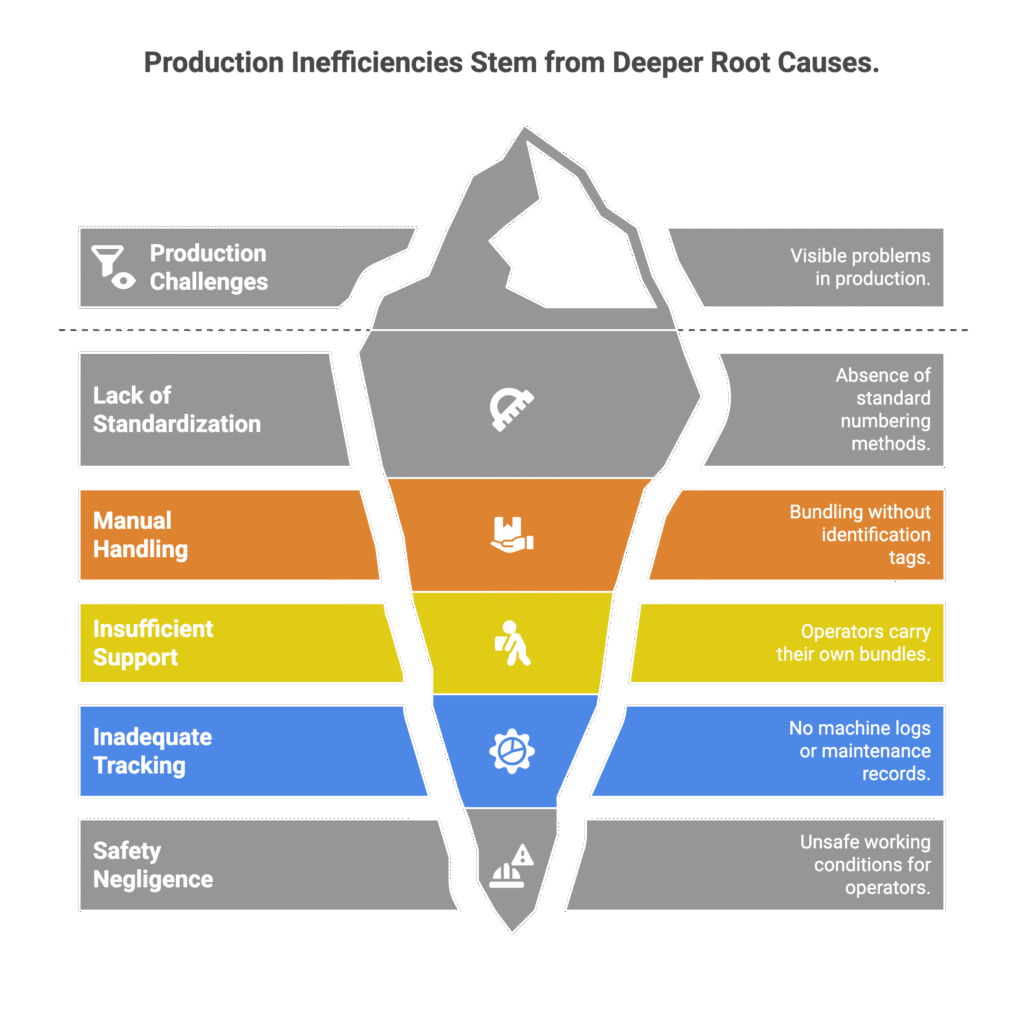

🔎 Common Challenges Observed in Production Process:

- Lack of standard numbering techniques.

- Manual bundling without identification tags.

- No helper support — operators carry their bundles.

- No machine logs or maintenance tracking.

- Unsafe working conditions (no gloves at band knife, no protective gear).

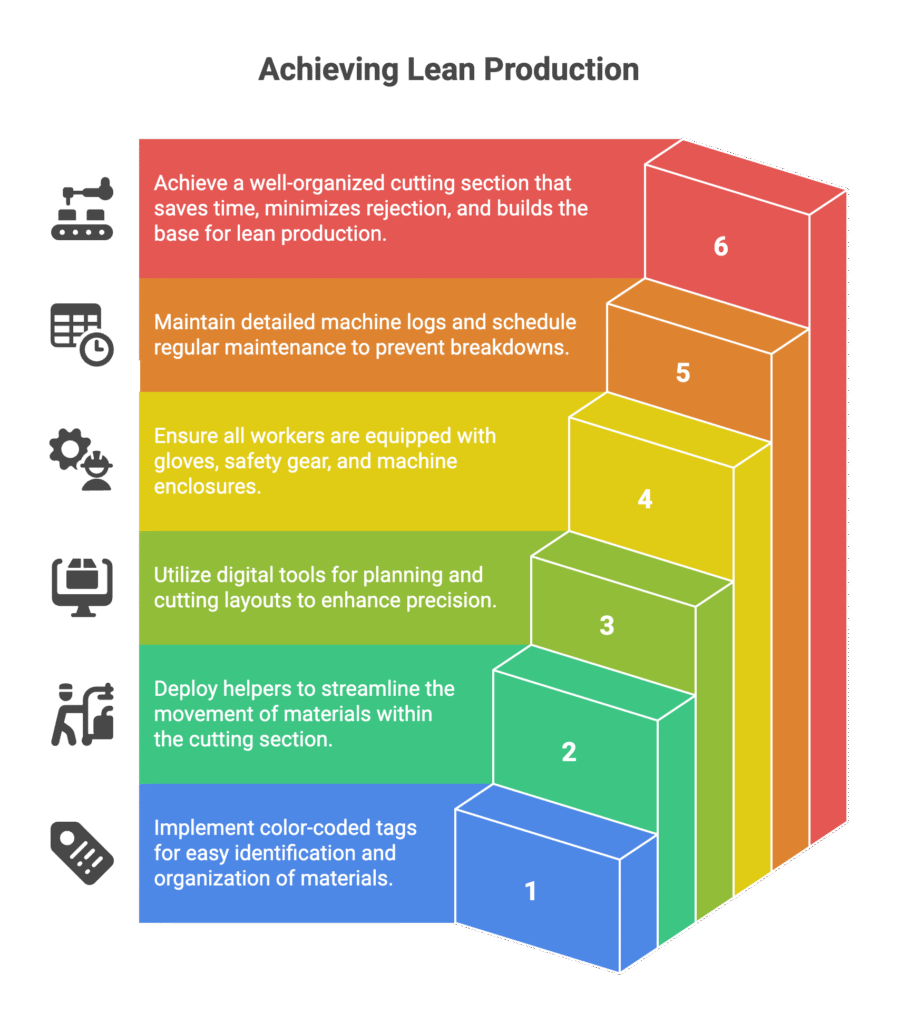

✅ Suggested Improvements:

- Use of color-coded bundle tags.

- Deployment of helpers for material movement.

- Digital marker planning and cutting layouts.

- Gloves, safety gear, and cutting machine enclosures.

- Implementing machine logs and scheduled maintenance.

Cutting inaccuracies affect seam alignment, sizing, and lead to high defect rates down the line. A well-organized cutting section saves time, minimizes rejection, and builds the base for lean production.

🧵 3. Sewing Section – The Heart of Garment Manufacturing Production Process

The sewing section is the most labor-intensive and productivity-sensitive area in garment manufacturing.

Key Parameters for Sewing Efficiency in Production Process:

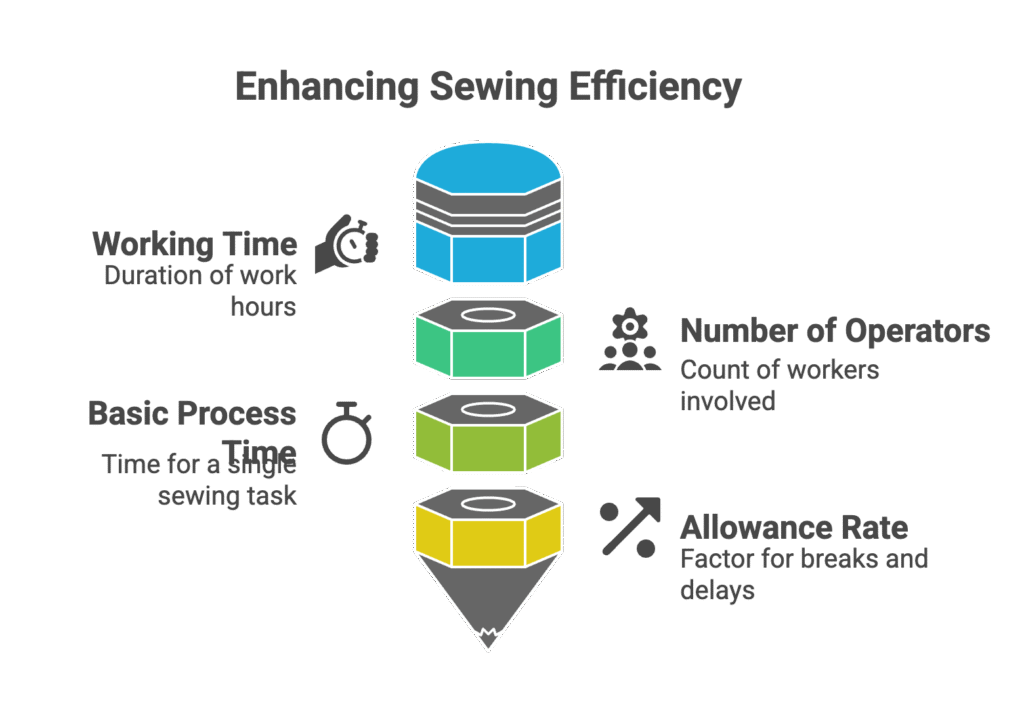

📈 Daily Work Flow Formula:

Daily Work = Working Time × Number of Operators

÷ [Basic Process Time × (1 + Allowance Rate)]

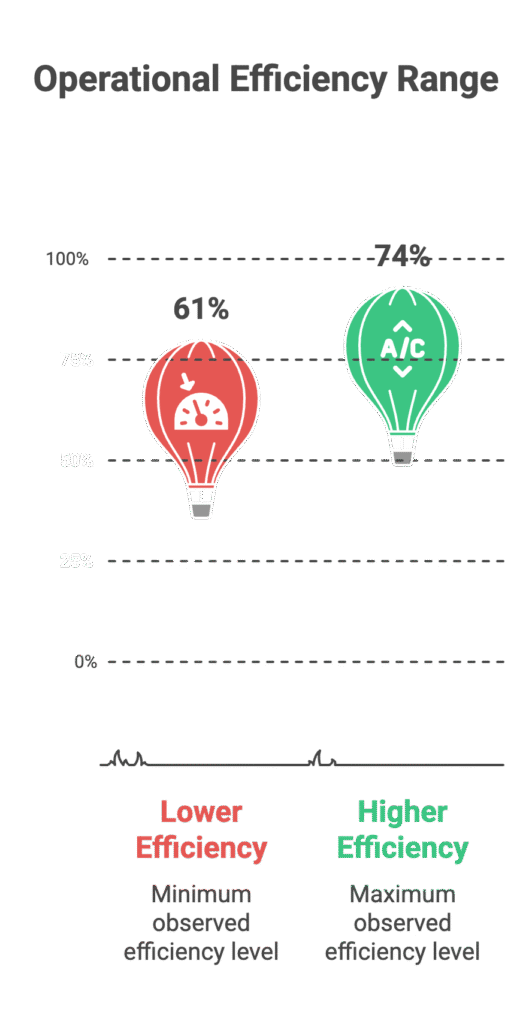

⚙️ Operational Efficiency:

Measured as:

Efficiency (%) = (Actual Output / Expected Output) × 100

In our observed studies:

- Actual line efficiency ranged from 61% to 74%, which indicates major room for improvement.

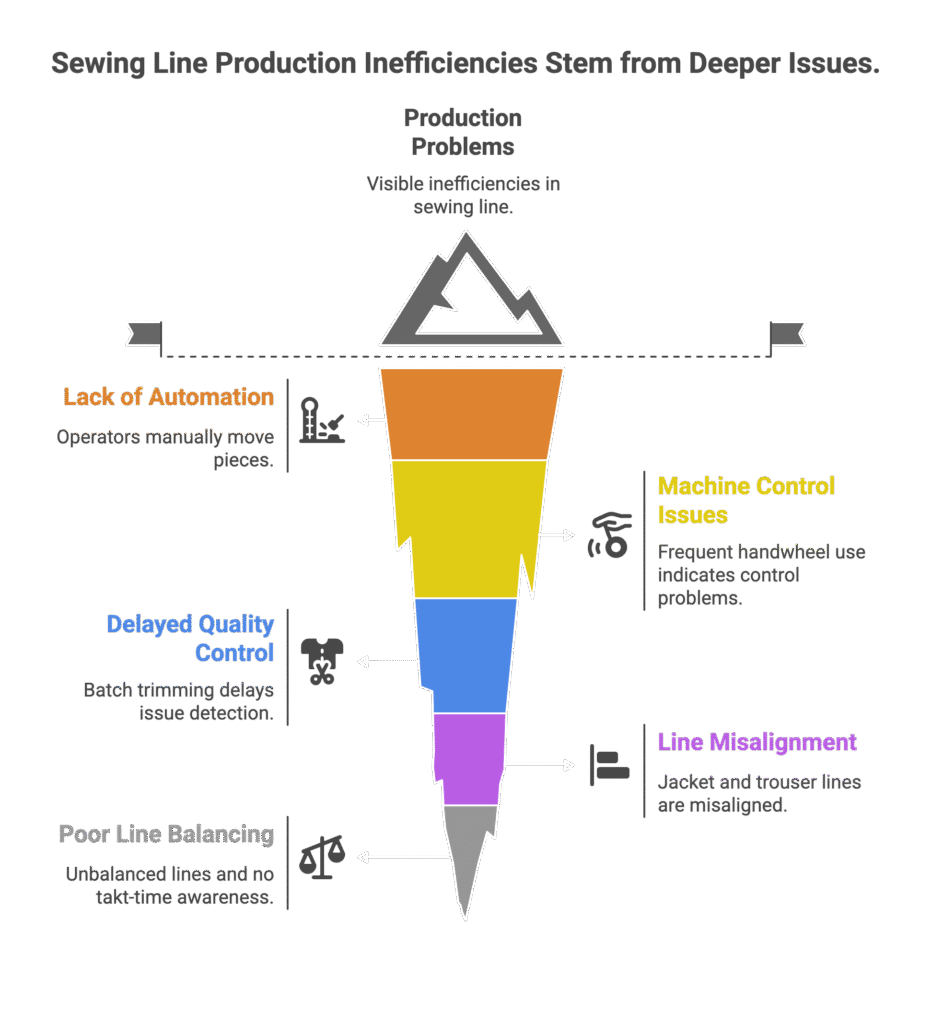

🧵 Observed Problems in Sewing Line Production Process:

- Operators doing their own piece movement (no helpers).

- Frequent use of handwheel due to lack of machine control.

- Batch-wise trimming, rather than inline quality control.

- Misalignment in jacket and trouser lines leading to pairing issues.

- Poorly balanced lines and no takt-time awareness.

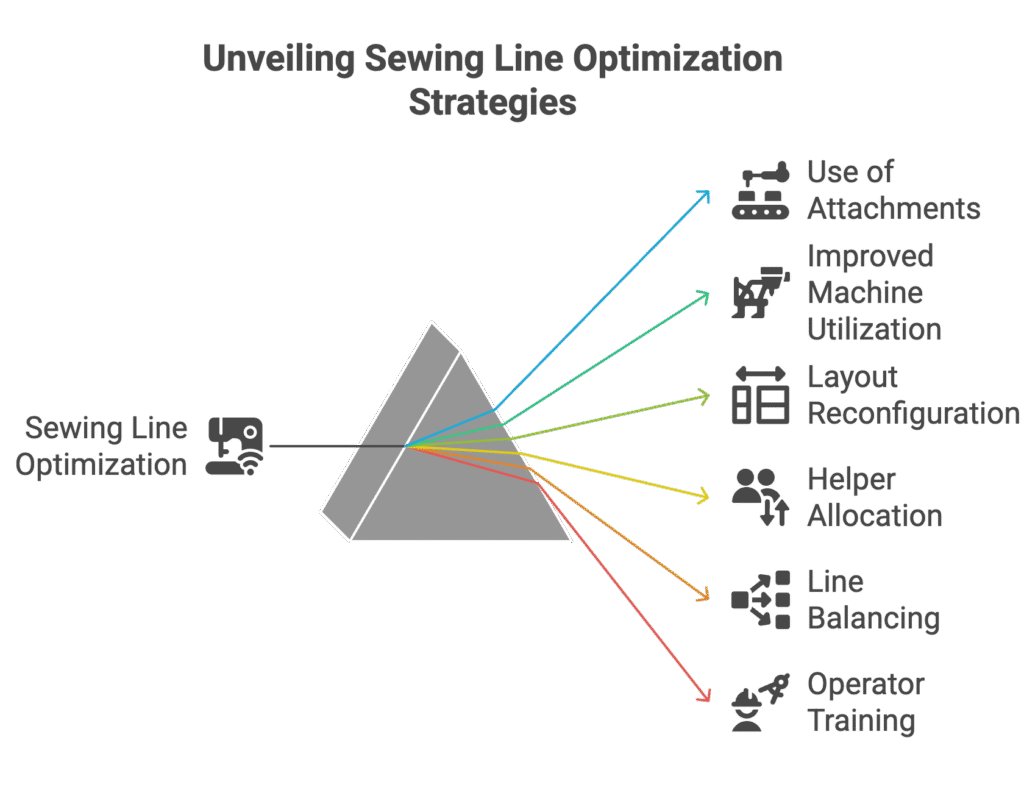

✅ Recommendations for Sewing Line Optimization:

🪡 a) Use of Attachments

Advanced machine attachments reduce manual handling and improve consistency.

🧰 b) Improved Machine Utilization

Switch to automatic thread trimmers, electronic feeders, or programmable machines.

👥 c) Layout Reconfiguration

Create a U-shaped or straight-line layout with optimal material movement.

🔄 d) Helper Allocation

Assign dedicated helpers for input feeding and output collection to avoid operator fatigue.

🎯 e) Line Balancing

Distribute work content evenly across operations using standard allowed minutes (SAMs).

📝 f) Operator Training

Focus on multi-skilling and sewing techniques improvement.

A well-managed sewing section can lead to higher output, reduced rework, better ergonomics, and eventually, greater profitability.

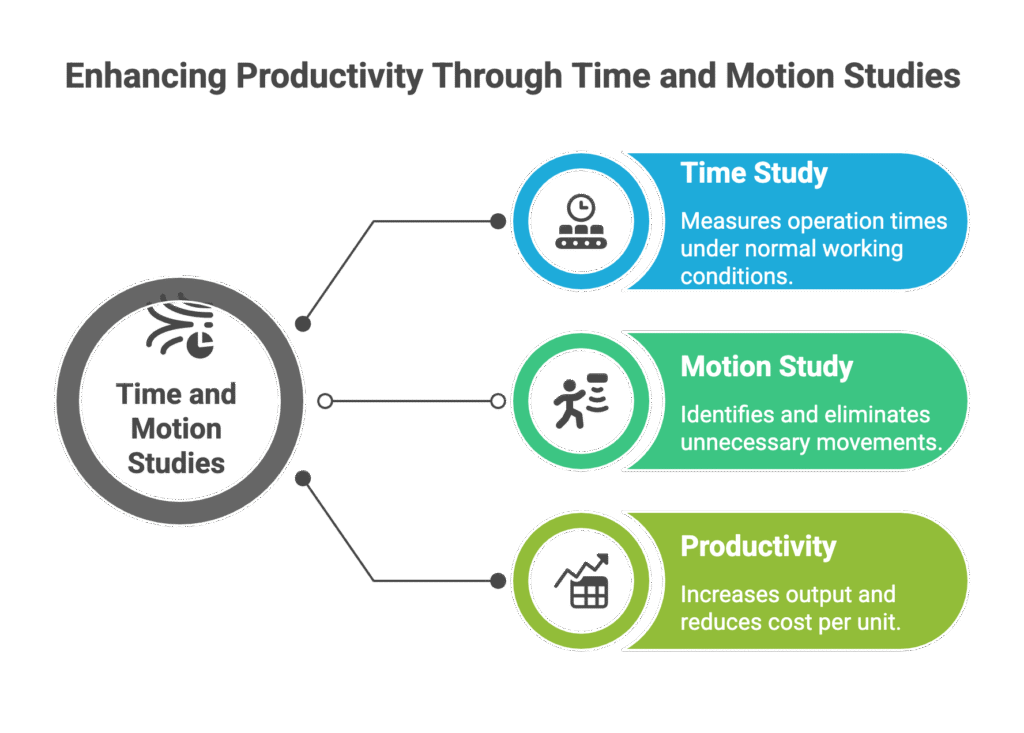

⏱️ 4. Time Study, Allowances, and Productivity

To maximize output and reduce cost per unit, a time-motion study is essential.

⏱️ Time Study:

Analyzes how long each operation takes under normal working conditions.

💨 Motion Study:

Breaks down movements to eliminate inefficiencies or excess motion.

📊 Allowance Calculation in Production Process:

Accounts for unavoidable delays, fatigue, and personal time. Common allowance rates vary between 10% to 20%, depending on the work environment.

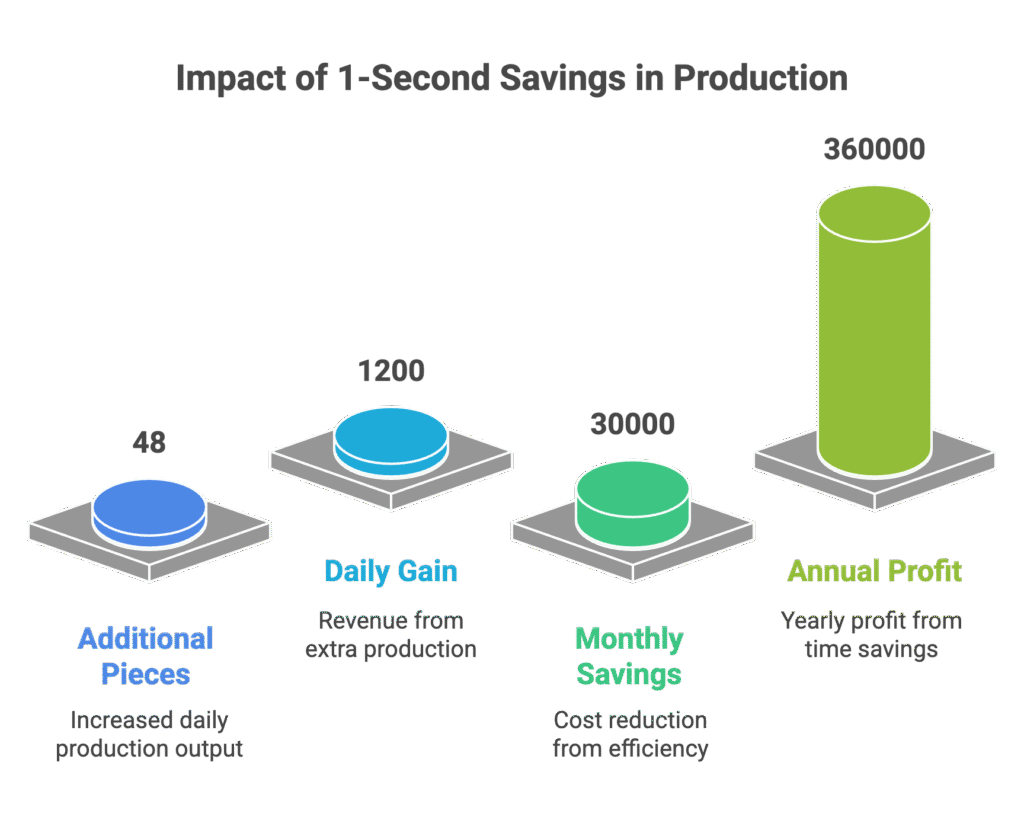

Real-World Impact in Production Process:

Even 1-second savings per operation results in:

- 48 additional pieces per day

- ₹1,200/day gain

- ₹30,000/month savings

- ₹3.6 lakh/year in profit

By implementing small improvements in operator motion or machine response time, factories can drastically scale up their profitability without increasing headcount.

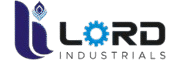

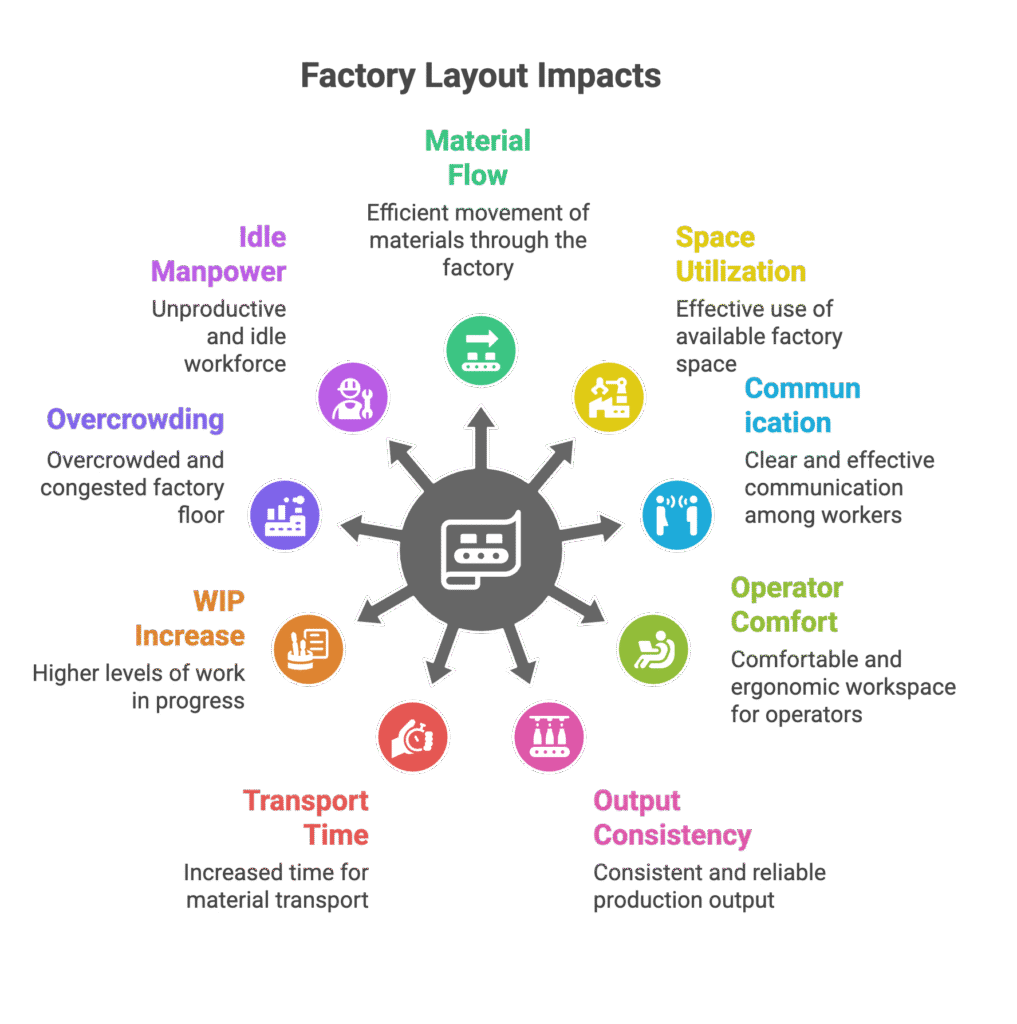

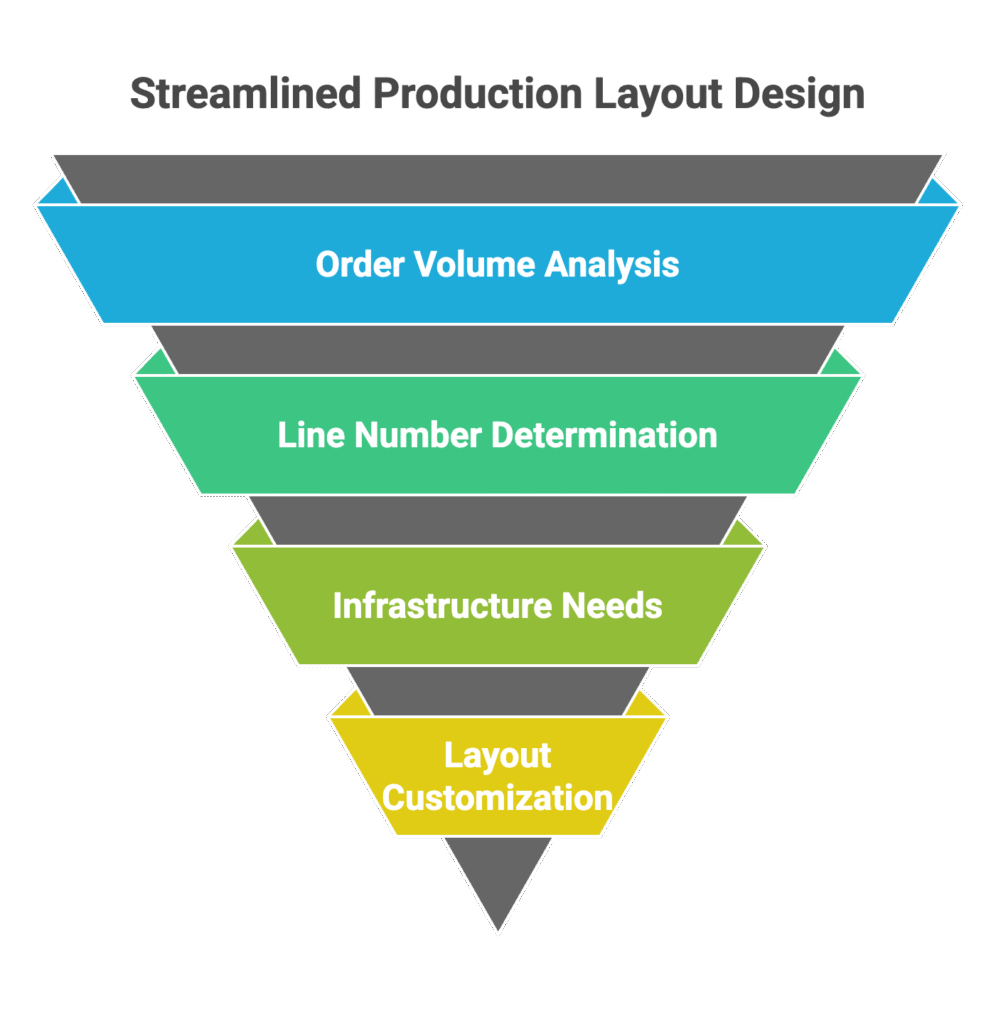

🏗️ 5. Factory Layout Planning – Foundation of Productivity

Factory layout design directly impacts the following:

- Material flow

- Space utilization

- Communication

- Operator comfort

- Output consistency

A poor layout increases:

- Transport time

- WIP (Work in Progress)

- Overcrowding

- Idle manpower

At Lord Industrials, we custom-design Phase 1 Layouts based on the product category (woven/knit), order volume, number of lines, and utility infrastructure needs.

Our layout planning ensures:

✅ Clear flow from cutting → sewing → finishing

✅ Buffer zones for WIP

✅ Centralized inspection area

✅ Optimized aisle widths and lighting

✅ Reduced cross-traffic and operator fatigue

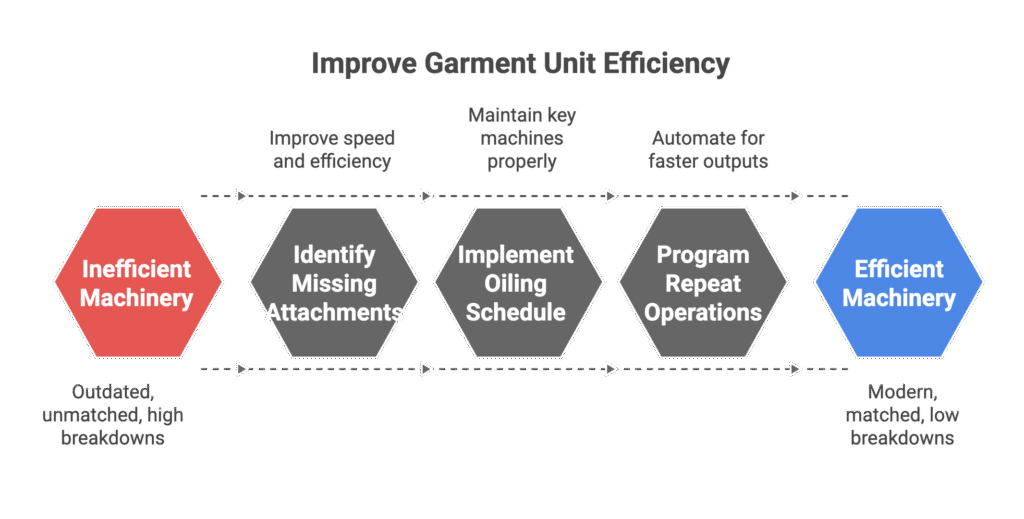

⚙️ 6. Machinery Analysis & Recommendations

Often, garment units run with outdated or unmatched machines leading to:

- High breakdowns

- Low precision

- Excess labor dependency

- Slower outputs

Our machine audits have revealed:

- Missing attachments that could improve speed

- No oiling/logs on key machines

- Lack of programmable settings for repeat operations

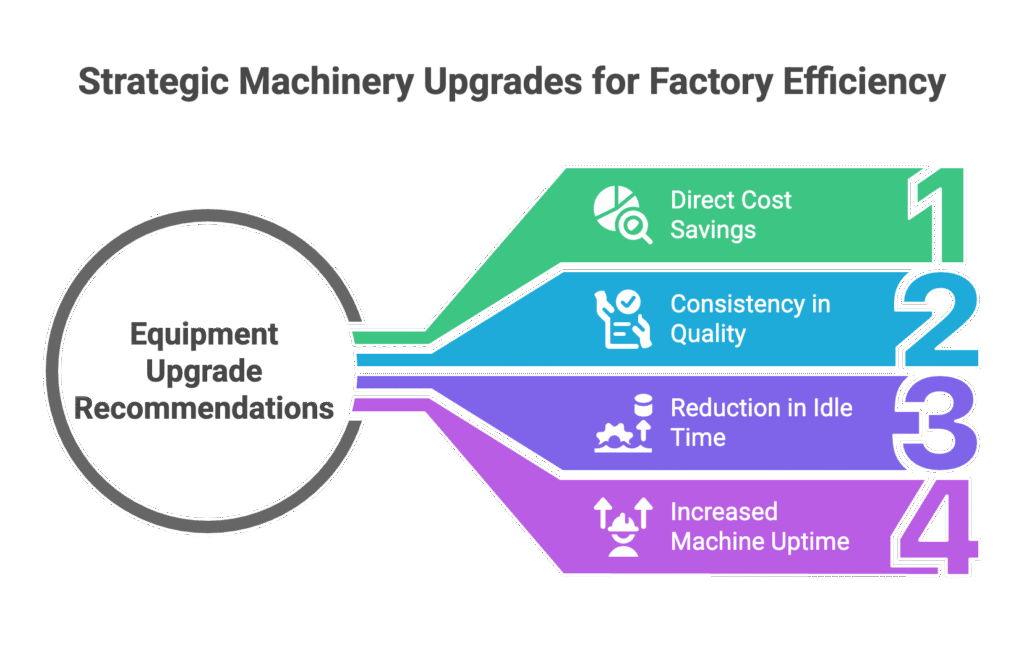

✅ Equipment Upgrade Recommendations:

- Use electronic sewing machines with programmable stitch patterns.

- Install automatic thread trimmers and folders.

- Use pneumatic lifting tables or stackers in the cutting section.

- Implement mechanical feeding arms in heavy operations.

By upgrading machinery strategically, factories can achieve:

- Direct cost savings

- Consistency in quality

- Reduction in idle time

- Increased machine uptime

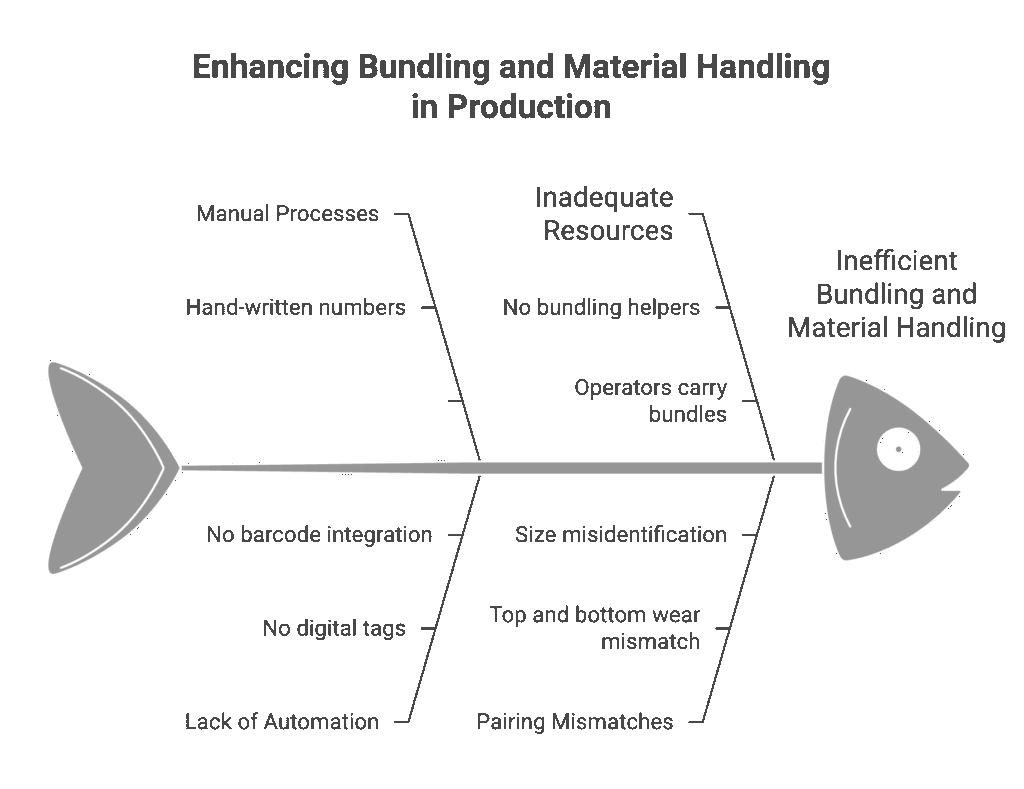

📦 7. Bundling & Material Handling in Production Process

Bundling ensures organized flow and tracking of cut pieces into the sewing line.

Existing Issues:

- Manual hand-written numbers on each ply

- No bundling helpers

- Operators carry bundles, losing production time

- Pairing mismatch between top and bottom wear

- No tracking tags

✅ Suggested Improvements:

- Digitally printed bundle tags

- Color-coded tags per size

- Use of trolleys and bins for transport

- Assign helpers for material movement

- Barcode integration for real-time tracking

These changes contribute to improved line feeding, lower missing parts, and smoother garment matching.

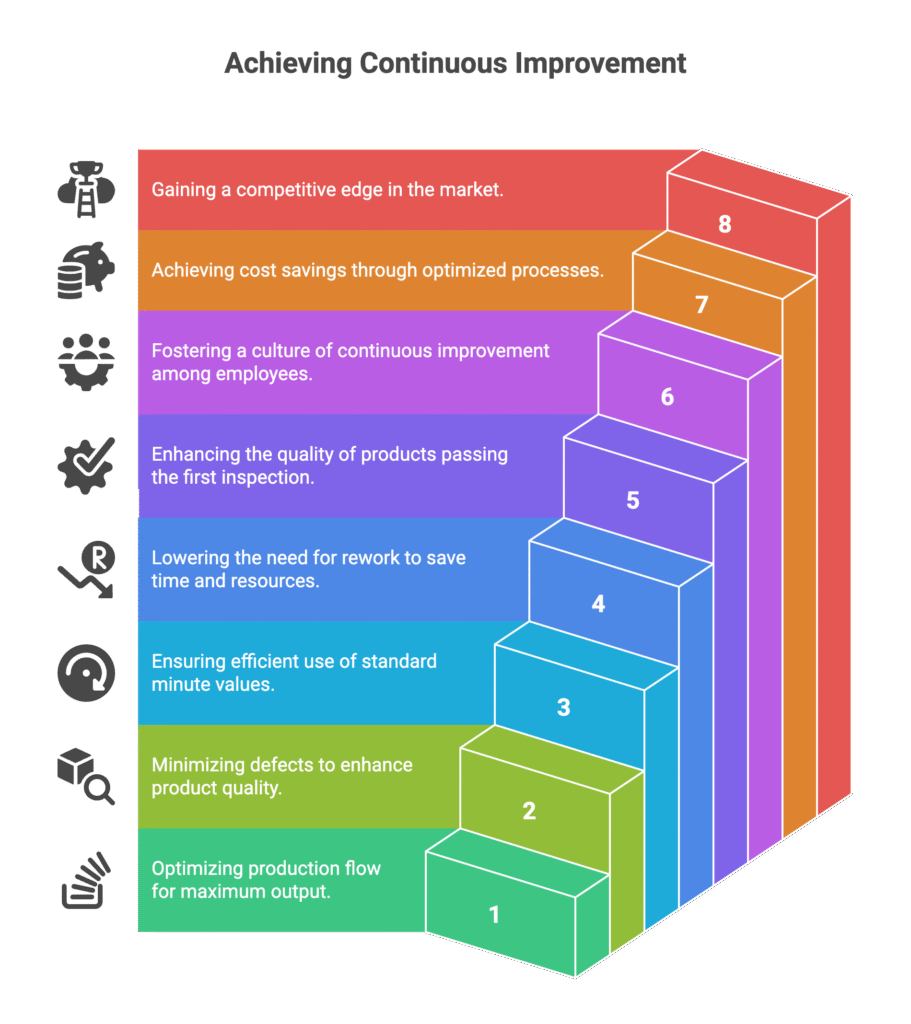

📈 8. KPIs & Kaizen Culture for Continuous Improvement

For factories to grow sustainably, tracking key performance indicators (KPIs) is vital.

Important KPIs to Monitor in Production Process:

- Line Efficiency

- DHU (Defects per Hundred Units)

- SMV Utilization

- Rework Ratio

- First Pass Quality (FPQ)

Introducing a Kaizen Culture helps in involving the workforce in incremental improvements. Every second saved, every motion optimized, contributes to cost control and market competitiveness.

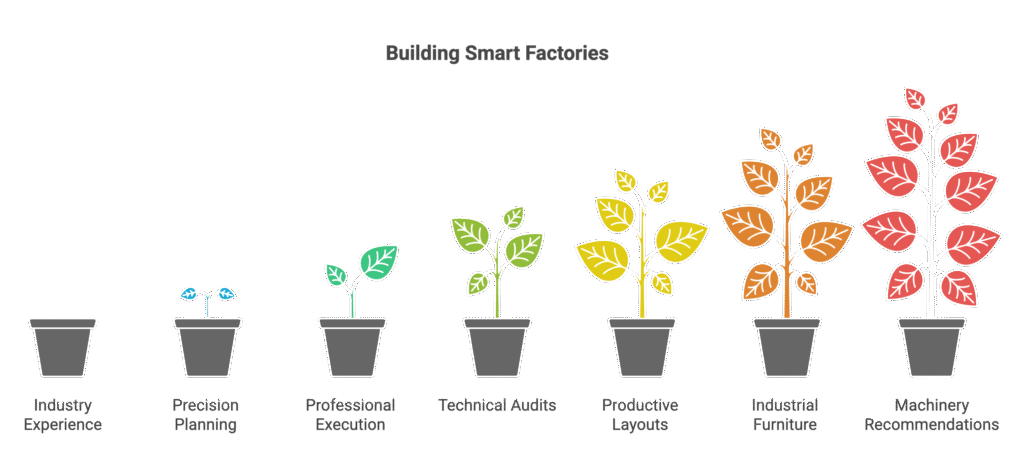

🔚 Conclusion: Build Smart Factories with Lord Industrials

Setting up and running a productive garment factory requires technical insights, industrial logic, and operational discipline. At Lord Industrials Pvt. Ltd., we help businesses unlock productivity potential through:

- 29 years of Industry experience

- Precision factory planning

- Professional execution

- Technical audits

- Productive layouts

- Industrial-grade furniture & trolleys

- Machinery recommendations

🎯 Why Choose Lord Industrials?

- Turnkey projects from concept to commissioning

- In-house manufacturing of industrial furniture, racks, and trolleys

- Trusted partner for garment, jute, leather, and textile industries

- SME-focused, cost-efficient, and execution-driven

Let’s build efficient, scalable, and future-ready factories together.

🔗 Visit us at: www.lordindustrials.com

📞 Call or WhatsApp: +91- 7603035011, 7603053011

📧 Email: info@lordindustrials.com