Garment factory setup modern jeans manufacturing facility capable of producing 10,000 pieces of 5-pocket denim jeans per day requires careful planning, efficient layout design, proper selection of machinery, utility planning, and end-to-end execution. At Lord Industrials Pvt. Ltd., we specialize in providing turnkey garment factory setup solutions, and this post outlines the major project requirements for such a high-capacity production unit, based on our recent work with one of the important client.

Table of Contents

Toggle1. Production Capacity Assumptions

Daily Output Target: 10,000 pieces/day

Monthly Output: 250,000 pieces

Annual Output: 3 million pieces

Production Shift:

Cutting & Washing Sections: 2 shifts (8 hours each)

Sewing, Finishing & Packing Sections: 1 shift (12 hours)

Efficiency Assumed: 70-80%

Absenteeism Considered: 15%

This estimation ensures realistic projections and helps structure machinery needs, manpower, and infrastructure accordingly.

2. Production System: Progressive Bundle Unit (PBU)

To ensure continuous and balanced workflow, the production system is designed using the Progressive Bundle Unit (PBU) method. This system allows for:

Easy movement of parts in trays or trolleys

Better Work-in-Progress (WIP) management

Improved line balancing and reduced bottlenecks

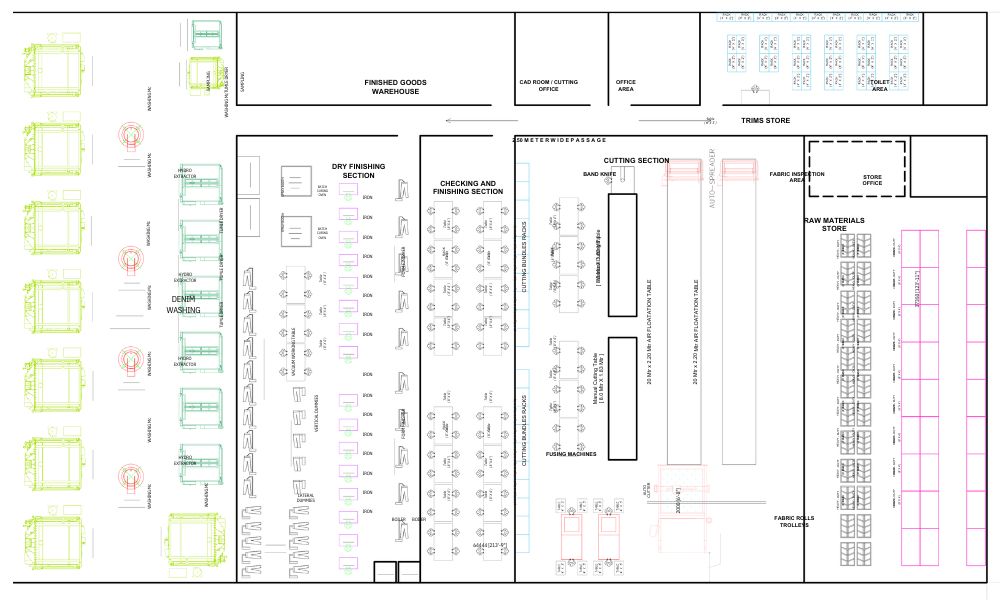

3. Space and Building Layout for Garment factory setup for Jeans Pants (10,000 pieces/day)

A well-designed space is crucial for efficiency, safety, and scalability. The project proposes a two-floor setup with designated areas:

-

Ground Floor:

-

Raw Material Storage

-

Cutting Section

-

Washing & Finishing Units

-

Packing & Dispatch

-

Finished Goods Storage

-

-

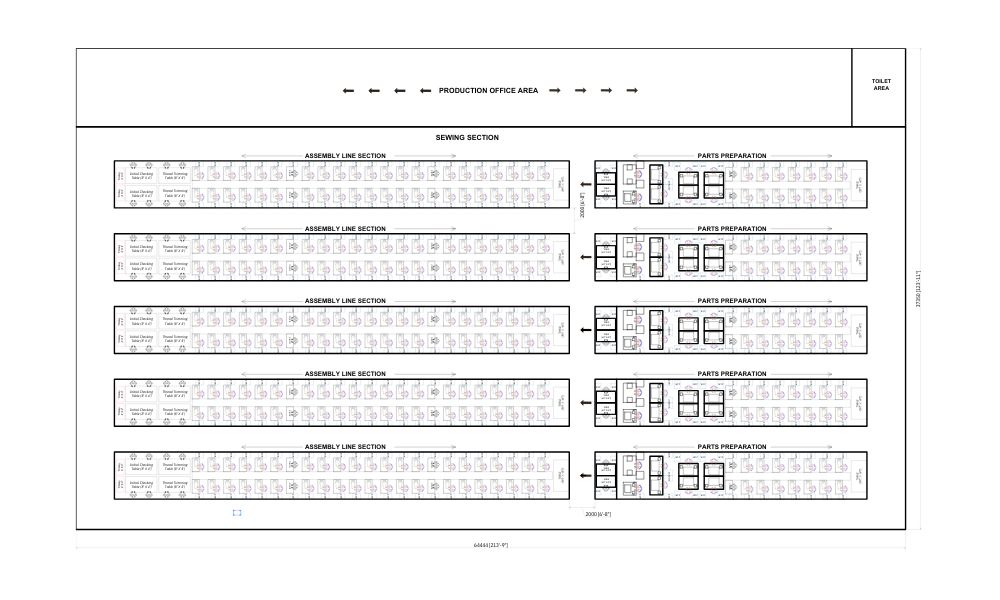

First Floor:

-

Sewing Lines

-

Parts Preparation

-

Inspection and Quality Control

-

Total Area Required: Approx. 50,000 sq. ft. of covered space.

4. Machinery & Equipment for Garment factory setup for Jeans Pants (10,000 pieces/day)

a) Cutting Room Equipment

Includes both automated and manual machines for bulk cutting:

CAD Software (Morgan / Lectra)

Plotter (72 inch)

Automatic Spreader Machines

Automatic Cutting Machine (Morgan / Lectra)

Air Floatation & Manual Cutting Tables

Band Knife, End Cutter & Straight Knife Cutting Machines

Continuous Fusing Press Machines

Investment: ₹1.83 Crores

b) Sewing Section Machinery

A mix of general and specialized sewing machines ensures versatility and precision:

1-Needle & 2-Needle Lockstitch Machines

Overlock (3-thread & 5-thread) Machines

Pocket Setters & Pocket Creasers

Chainstitch & Pattern Sewer Machines

Belt Loop Attachers & Button Holing Machines

Bartacking & Snap Attaching Machines

Total Machines: 305 Units

Investment: ₹4.62 Crores

c) Finishing & Pressing Equipment

Vacuum Ironing Tables

Form Finishers

Thread Sucking Machines

Trouser Frames (Vertical & Horizontal)

3D Pleating Machines

Brushing Machines

Spray Booths

Investment: ₹1.11 Crores

d) Washing Department Setup

Designed to support daily washing of 10,000 jeans:

6×400Kg Heavy Washing Machines

Tumble Dryers

Hydro Extractors

Sample Wash Equipment

Total Water Requirement: 3.0 Lakh Litres/day

Investment: ₹3.21 Crores

5. Utilities & Infrastructure for Garment factory setup for Jeans Pants (10,000 pieces/day)

a) Power Supply Requirements

Connected Load: ~464 KW (1-Phase), 244 KW (3-Phase)

Running Load: ~318 KW (1-Phase), 160 KW (3-Phase)

Recommended Transformer: 450 KVA

Backup DG Generator: 1 unit

Electrical Setup & Erection: ₹2.5 Crores

b) Compressed Air

Required Air Volume: 237 CFM

Recommended Air Compressor: 75 HP

Investment in Air System: ₹35 Lakhs

c) Steam Requirements

Daily Steam Need: 1,550 Kg/hour

Recommended Boiler: 2 Tonne capacity

Total Boiler & Assembly Setup: ₹1.3 Crores

d) Water Treatment & Safety Systems

ETP Plant: 3.00 Lakh Litres/day

RO Plant & Pipelines

Fire Hydrant and Alarm Systems

CCTV, PA System, and Biometric Access

Investment in Utilities & Electronics: ₹2.18 Crores

6. Production Furniture & Handling Equipment for Garment factory setup for Jeans Pants (10,000 pieces/day)

Industrial furniture improves operational flow, worker comfort, and workplace safety. Items include:

Operator Workstations with Light & Fan

Manual and WIP Tables

Racks (Light, Medium, Heavy Duty)

Trolleys (Fabric Roll, Flat, WIP, Net Trolley)

Pallets, Lockers, Shoe Racks

Canteen Tables & Benches

Total Quantity of Items Supplied: 2,000+

Investment: ₹1.18 Crores

7. Manpower Requirement for Garment factory setup for Jeans Pants (10,000 pieces/day)

Sewing Line Workers per Line: ~40

Finishing Section Workers per Line: ~14

Total Number of Workers (Sewing + Finishing): ~530+

Includes line supervisors, helpers, pressers, QC staff, and material handlers.

8. Operational Summary for Garment factory setup for Jeans Pants (10,000 pieces/day)

| Component | Details |

|---|---|

| Daily Output | 10,000 Pieces |

| Efficiency | 70–80% |

| Space Requirement | 50,000 Sq. Ft. |

| Machines Needed | 300+ |

| Power Load | ~350 KVA |

| Water Requirement | 3.00 Lakh Litres/day |

| Steam Requirement | 1,550 Kg/hr |

| Manpower | 500+ |

| Total Project Cost | ₹18.28 Crores (Approx.) |

9. Key Project Features for Garment factory setup for Jeans Pants (10,000 pieces/day)

Turnkey Execution by Lord Industrials Pvt. Ltd.

Precise Electrical & Mechanical Planning

Customized Layout Design to maximize efficiency

In-House Supply of Furniture and Handling Equipment

Optimized Utility Planning with provision for future scaling

Factory Built for Safety, Productivity & Sustainability

10. Why Choose Lord Industrials Pvt. Ltd.?

We are a trusted partner for industrial project execution. Our services include:

Complete project planning and feasibility studies

Plant layout and workflow design

Machinery selection and procurement support

On-site project management and execution

In-house manufacturing of furniture, racks, and trolleys

Compliance with safety and environmental regulations

Post-project support and scaling solutions

We follow the Skill – Speed – Scale (S-S-S) model to ensure on-time, in-budget, and future-ready factory setups.

Conclusion

Setting up a factory to manufacture 10,000 jeans pants per day is a complex project that demands engineering precision, industrial insight, and seamless coordination between teams. From utility systems and machinery selection to furniture and layout — Lord Industrials Pvt. Ltd. ensures every aspect is addressed professionally.

If you’re looking to start or expand your denim manufacturing unit, we are ready to help you plan, build, and launch a factory that delivers performance, quality, and scalability.

📞 Contact Us Today to discuss your factory project!

🌐 Visit: www.lordindustrials.com

📧 Email: info@lordindustrials.com

📱 Phone/WhatsApp: +91-7603035011 / 7603053011 / 7603059695